Flow-induced vibrations (FIV) in nuclear power plants can have serious consequences on the structural integrity and safety of the plant. These vibrations occur when fluid flow, such as water or steam, causes structures or components to oscillate or move in a repetitive manner. The vibrations depend on a variety of factors, among others the geometry of the plant component, its fixation within the plant construction, the flow characteristics of the surrounding fluid, and the properties of the materials used in the construction of the plant.

The integrity of the nuclear steam supply system (NSSS) of a nuclear power plant (NPP) is essential for its safety and operability. Key NSSS components such as fuel assemblies (FA) or steam generator (SG) tubes are subject to several ageing challenges like high multiple corrosion mechanisms, neutron flux (embrittlement), and also long-term vibratory loads. Vibrations induced by coolant flow are particularly important challenges, as they lead to increased wear and tear and/or material fatigue. They have been and remain important contributors to the failures of key components. Such failures can degrade NPP safety features and fail confinement barriers. According to IAEA grid-to-rod-fretting wear (GTRFW) resulting from such vibrations is the cause of 58% of fuel failures in PWRs worldwide and one of the major causes of fuel failure in boiling water reactors (BWRs). The highly turbulent coolant flow in FA during operation results in asymmetric and fluctuating pressure on the fuel rods’ surfaces. The pressure fluctuations are random, oscillate over a broad band of frequencies and amplitudes over the entire rod surface. This leads to dynamic grid-to-rod contacts and frictions, resulting in material wear in the contact region between the rod and its support.

FIV also causes damage in SG. In 2012, an SG tube rupture (SGTR) occurred, and thereafter, extensive wear of more than 3000 SG tubes was found in San Onofre NPP units 2 and 3, leading to primary coolant leaks. The SGs in these units were put into operation one year earlier. The principal reason for the extensive wear and tube damage was found to be related to FIV. The US NRC identified violations of 10 CFR Part 50, Appendix B, Criterion III, for the failure to verify the adequacy of the thermal-hydraulic and FIV design of the San Onofre replacement SGs, which resulted in excessive and unexpected SG tube wear after one cycle of operation (NRC, 2015). Since then, these units are in a shut-down condition pending decommissioning. Steam generator tube rupture as a result of FIV has also been observed in other reactors in the past.

To prevent flow-induced vibrations in nuclear power plants, several measures can be taken. These include designing plant components with appropriate geometry and flow characteristics and using materials that are resistant to fatigue, vibration, and erosion. In addition, plant operators can implement measures such as installing vibration dampers or altering the flow of the fluid to mitigate the risk of vibrations. Flow-induced vibrations can also be monitored and managed by using sensors and vibration analysis techniques. These technologies can help identify areas of the plant that are at risk for vibrations and allow operators to take proactive measures to prevent problems before they occur.

The overall objective of GO-VIKING is to increase the expertise and improve the tools and skills of the European nuclear stakeholders for the analysis of complex FIV phenomena. This will be accomplished by:

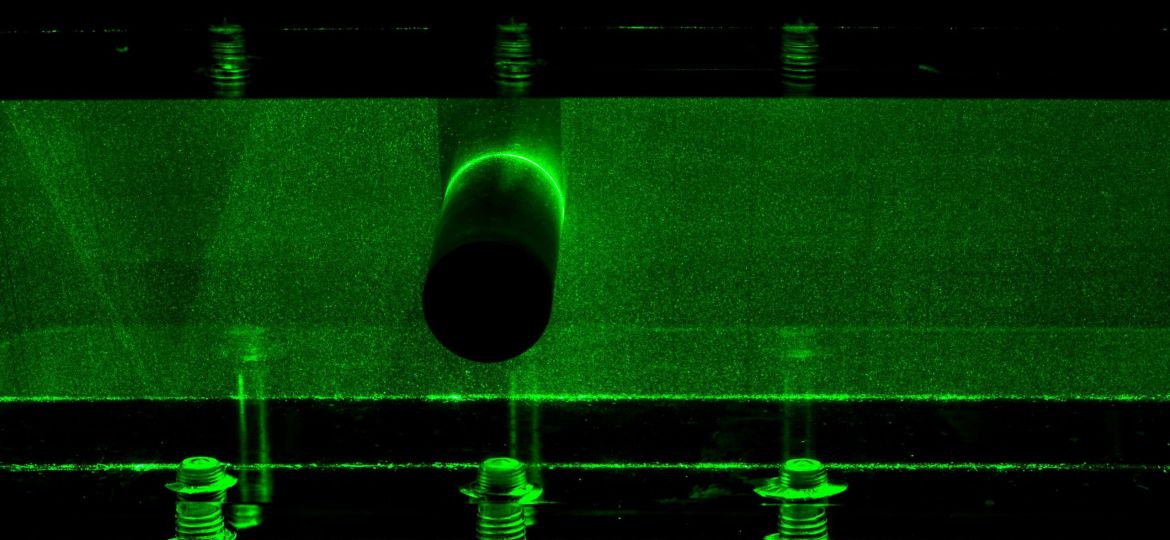

- Generation of new experimental and high-resolution numerical data, relevant to nuclear fuel assemblies and steam generators

- Expanded knowledge on efficiency, accuracy, and reliability of fluid-structure interaction (FSI) methods

- Provision of validated fast-running FSI tools with uncertainty quantification methods

- Highly increased expertise and awareness of FIV phenomena in nuclear power plants

- Training of stakeholders and graduates in numerical FIV analysis

To summarize, flow-induced vibrations are a serious concern in nuclear power plants, as they can lead to component damage, failure, and even nuclear incidents. By gathering and disseminating expertise on flow-induced vibrations with numerical and experimental analysis, and developing and validating advanced numerical tools for their prediction in the GO-VIKING project, the risk of vibrations can be minimized, and the operation, safety, and reliability of the plants can be increased.